Why Is Proper Food Storage Important?

The perishable products we consume require storage within a certain temperature range. When you store food the right way, it prevents the food products from going bad and preserves its quality. It also helps prevent bad germs from growing. This keeps your food safe to eat and stops things like raw meat from making other foods unsafe. Proper storage means you get to use up your food before it goes bad, which saves you money and resources.

Storing the food products outside the recommended temperature range could drastically increase its perishability. Food products that could be stored for months will only last a few days outside the appropriate environment.

Refer to the image below for a guideline on food products storage temperature range.

Image from Singapore Food Agency

What Is A Temperature Monitoring System?

Businesses manage multiple cold rooms, freezers, and chillers. This is to accommodate the various temperature ranges needed for storing various food products.

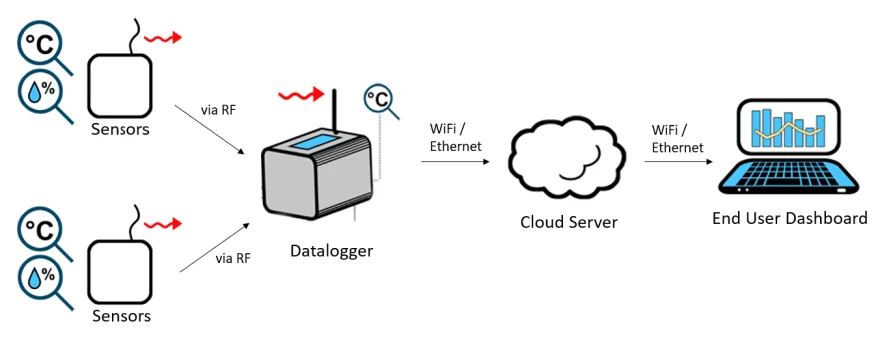

These cold storage equipment’s includes a default temperature monitoring system provided by the vendor. But, it lacks certain features required for businesses to maintain constant optimal temperature conditions for their food products. This is why investing in an external wireless temperature monitoring system is ideal.

So, what is a temperature monitoring system? A temperature monitoring system measures, monitors and automates temperature data recording of the environment it oversees. There are many scenarios that requires a temperature monitoring system. These industries will need a temperature monitoring system;

- Food & Beverage (cold storage equipment’s etc.),

- IT (data centre servers, server room ambient temperatures etc.),

- Healthcare (laboratories, pharmaceutical, hospital medication/vaccine storage etc.).

In this case, the temperature monitoring system is used to monitor cold storage equipment’s. Click here to read through a success story on this.

A temperature monitoring system is essential not just for safeguarding your food products. It also brings a good return-on-investment. As it prevents the loss of assets and enhancing efficiency.

How Does A Temperature Monitoring System Help?

-

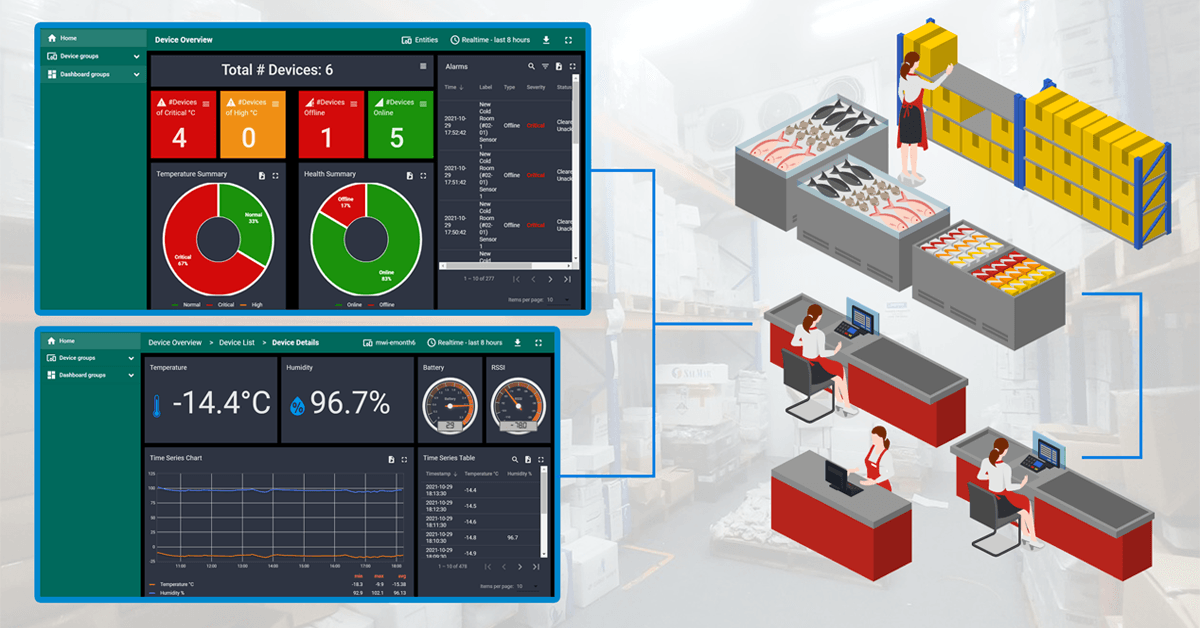

Real-Time Monitoring Of Temperatures In One Screen

A wireless solution monitor temperatures in all cold rooms, freezers, and chillers comprehensively. Monitoring the environment of all your cold storages will occur from a single screen. This eliminates the need to switch between systems for monitoring your cold rooms and freezers.

You can also remotely monitor the temperatures of your cold rooms and freezers from anywhere with the web application, via your phone or computer.

-

Alert Notifications

Most temperature monitoring systems come equipped with an alert function. It notifies the user of temperature deviations in the storage environment due to multiple scenarios. Some scenarios include; forgetting to close the fridge, or cooling system going offline. The alert can help to save large amount of these food assets, especially for businesses.

-

Generate Temperature History Logs For Audit Purposes

When businesses undergo audits by their regulatory bodies, auditors often request specific documents. One of which includes the temperature history logs of all your cold storage equipment’s. With the temperature monitoring system in place, it automates the recording of data. The business can generate the temperature historical logs from the web application and pass it to the auditors. This reduces the amount of work the employees have.

This convenience frees up manpower which was previously required to perform the monitoring of all your cold storage. Businesses can then move this manpower elsewhere to improve productivity.

What Should You Look Out For When Implementing Effective Temperature Monitoring?

The most important values to look at in a temperature monitoring system for food products, are the temperature and humidity levels. The environment of where the food products are stored must be cold enough. This preserves its quality & avoid moisture to prevent bacteria growth, leading to spoilage.

The minimum requirement of a temperature monitoring system for food products should be:

- Able to measure temperature range from -40°C to 125°C

- Able to measure humidity range from 0%RH to 80%RH

- Alert user of critical temperature detection / temperature deviation

- Able to generate temperature data records for audit purposes

FAQs

Several different features distinguish between the two.

- Accessibility For Monitoring Temperatures Of Cold Storage

A default cold room temperature monitoring system only allows employees to check and monitor the temperatures of the cold rooms and freezers through the control panel. Whereas, an external temperature monitoring system allows for remote temperature monitoring, be it via their phones or computers.

- Lesser Hassle Of Monitoring Cold Storage Temperatures