Project Summary

Company Profile

The Fish Farmer is a leading wholesale seafood distributor located in Singapore. The seafood distributor was founded back in 2007, supplying savoury, fresh and naturally grown fish to Singapore retailers such as NTUC FairPrice and Cold Storage, restaurants such as The Summerhouse and hotels such as PARKROYAL Hotels & Resorts. Their naturally grown fishes include; grey mullet, milk fish, seabass, red snapper and golden pomfret. The Fish Farmer is the only farm in Singapore that has the widest variety of fish as well as being 1 of the 4 Singapore Fish Farms that is Good Aquaculture Practice (GAP) certified, which makes them the preferred distributor for their customers.

MWI Product Used

The Solution

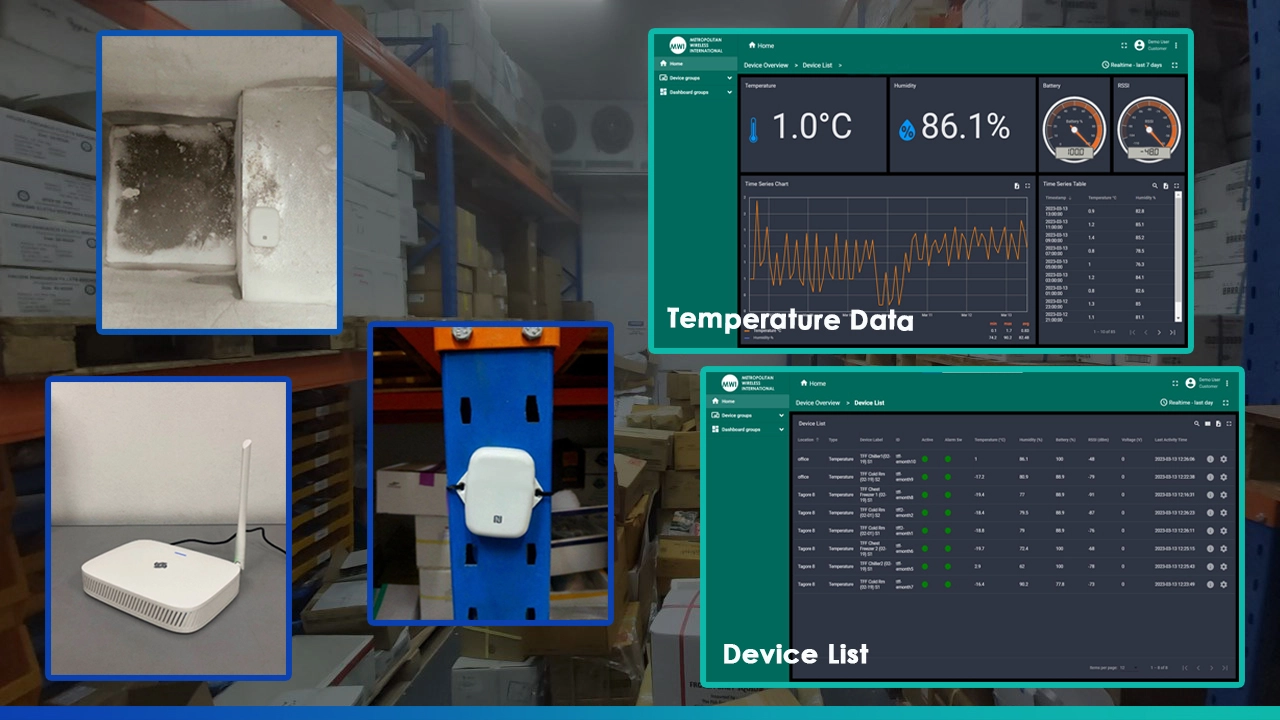

The Fish Farmer found that the ThermoCare product will help in monitoring and alerting them of temperatures of their cold rooms and chillers. The devices and system itself are simple to install and easy to use, where it consists of sensors that uses the LoRaWAN technology, a gateway, cloud server and a web application.

Sensors are placed inside the cold rooms and chillers to measure its temperatures and can be configured to automatically capture temperature data which will then be sent to the web application. Through the web application, it allows The Fish Farmer to monitor temperatures of their cold rooms and chillers remotely and extract temperature data from it so that they would be able to provide it to the SFA during audits. Alert notifications will also be sent if temperatures for their chillers and cold rooms crosses the threshold. This allows the distributor to make any necessary actions to ensure that their goods are stored within temperature range.

MWI also provides AI aquaculture fish farming systems. We use AI to count fish in fish farms. So this doesn’t have to be done manually.

Outcome

A written testimonial by Evonne Chow, The Fish Farmer’s Cold Room Operation Executive: “The most important reason why MWI’s temperature monitoring system is good is because we receive real time alert when temperature is high. It helps us to take immediate action to check and resolve the problem quickly so that we can prevent any damage of equipment or loss of goods. We can also remotely check the real time temperature data of our cold room and freezers.”

By using our ThermoCare product, The Fish Farmer is able to;

- Ensure that both the cold rooms and chillers are functioning,

- Monitor and ensure that cold rooms & chillers are kept within temperature requirements set by the SFA,

- Get alert notifications when temperatures goes above threshold,

- Ensure that the goods are within temperature range when delivered to customers so that the quality of the goods are not compromised,

- Ensure that the system automates temperature data recording so as to provide the SFA with relevant temperature data records during audits.