Customer Stories

ThermoCare System immediately alerted me about the temperature spike during the second day of Chinese Lunar New Year.

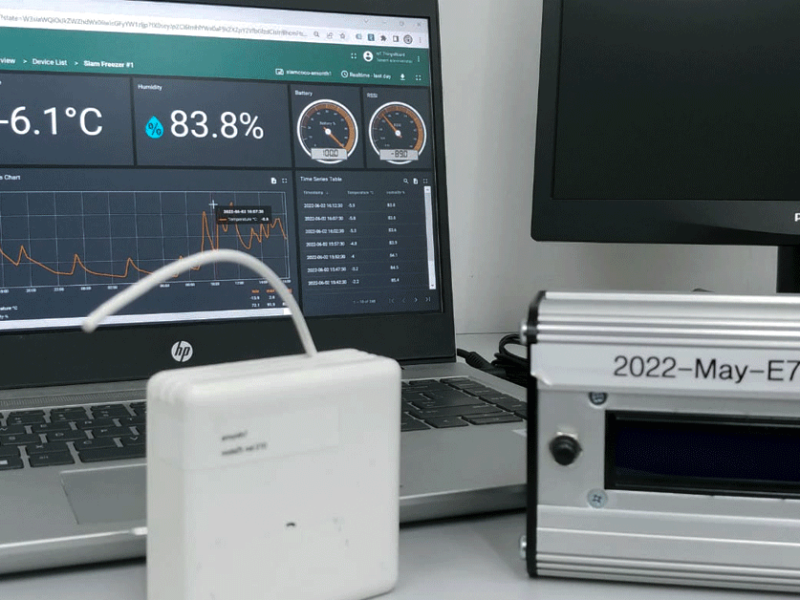

After I harvest my fishes, I will store them in my Cold-room & Freezers. I do not have 24/7 personnel to standby monitoring my Cold-room’s condition. This poses a worry if any of my Cold-room or Freezer were down/malfunctioning.

During Festive Season I had a downtime of my Cold-room during second day of Chinese Lunar New Year. ThermoCare System immediately alert me about the Cold-room’s Temperature spike.

Thanks to ThermoCare System I immediately informed the Cold-room supplier to rush down to investigate and mitigate my Cold-room Temperature issue.

If not for ThermoCare System, I could have lost a million dollar worth of Frozen-Fish Stocks during that incident on Chinese Lunar New Year.

– Evonne Chow, Coldroom Operation Executive

MWI is truly a one-stop shop for simple and straightforward IT Solutions. They provide a user-friendly interface with plug-&-play sensors.

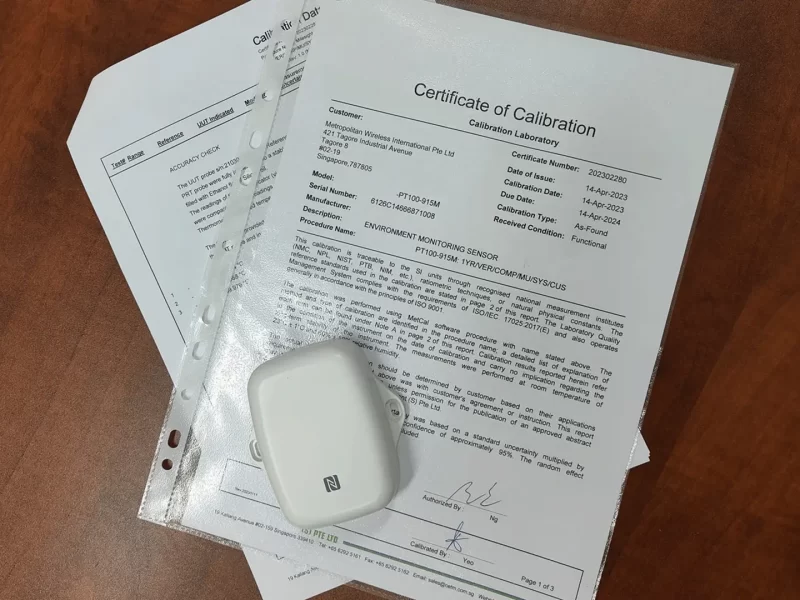

We had difficulties looking for a solutions provider that could provide sensors with calibration certification that traces back to the ISO/IEC 17025 standards.

MWI was able to provide sensors with calibration certificates as they are well connected with the calibration labs in Singapore. Their solution meets our requirement to monitor multiple location from a single dashboard remotely from anywhere at anytime.

The team is prompt with their response whenever we contracted them. We have never been left high & dry, and this is a very essential element of a good company to work with long-term.

– OncoCare Management

The temperature sensors does not get in the way of our operations because of their size and wireless technology!

Our previous monitoring system had a lot of cabling work which was invasive on our infrastructure and the sensors often got in the way of my workers who are trying to do their work.

MWI provided a solution that utilizes a plug-and-play type of sensors. The sensors are battery powered and transmit data wirelessly, so the installation of the sensors was hassle-free as they do not require additional cabling work.

They showed high level of professionalism throughout the procurement process, from our first inquiry to the post-sales service stage.

Their support is local and we can easily get in touch with them whenever we require their assistance, which is something we truly appreciate as well.

– Kelvin Ngian, General Manager

MWI provides professional advice, responsive assistance and 24x7 support, contributing to a positive and efficient customer experience!

Before the Hospital adopted a continuous automated temperature monitoring system, tracking of temperature for critical medication and items that required to be constantly chilled was done manually.

Staff had to physically inspect and record temperatures on hardcopy multiple times in a day. This posed a challenge to staff especially during peak hours.

Introducing the automated system not only relieved staff from doing the manual task, it also ensured that any temperature fluctuation beyond tolerable limits is immediately escalated for rectification.

Tracking now is consistent and alert is instantly triggered to the relevant party for immediate inspection.

– Bruce Leong, IT Director

ThermoCare System is essential to us in preparations for our audits, temperature reading and excursion logs are readily available online.

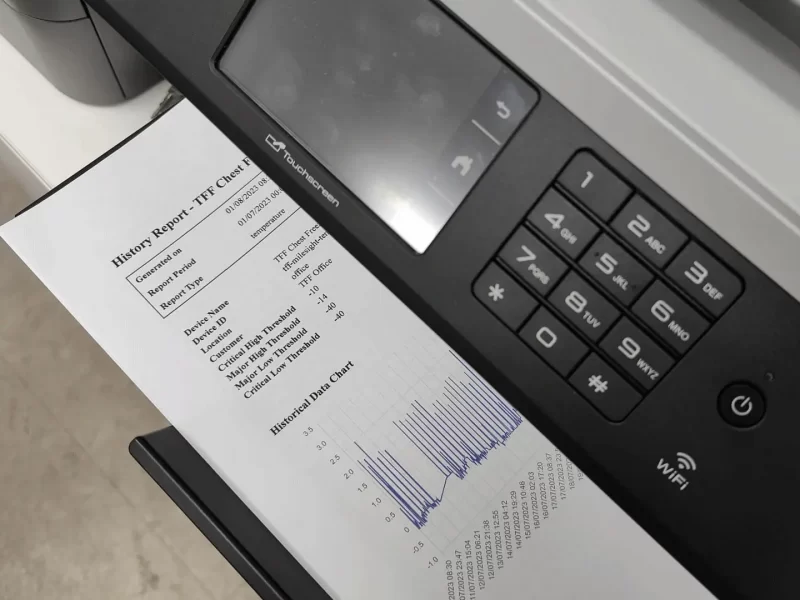

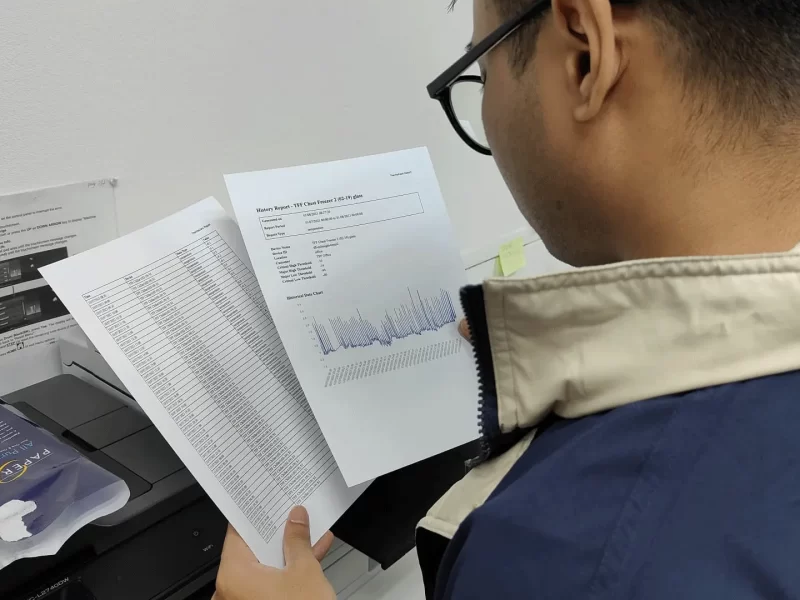

As we are accountable for the extensive quantity of samples in our lab, we are expected to implement a 24/7 monitoring system that can generate reports and history logs. This is a common requirement in our industry as medical products and samples are easily compromised when there is deviation in the storage environment.

MWI's ThermoCare System has a feature that automatically send history reports to our email on a monthly basis, and this saves us the hassle of having to export the history logs ourselves. This is especially helpful during surprise inspections when we do not have the luxury of time to extract the temperature log from the system.

The system gives us confidence in the security of our products and samples, which in turns gives confidence to our customer in the quality of our products and services.

– Toh Kai Yee, Head of Lab & Research

Features

Temperature Monitoring System

Real Time Remote Monitoring

Live Visual Data Feed

Temperature Logging

Alert Notifications

Export Data Reports

Temperature & Humidity Sensors

Our devices are wireless and portable, designed to be placed within refrigeration units (down to -40°C). We can measure temperature range from -200 to +800°C, relative humidity range from 0 – 100%, and an additional sensor can be installed into each device for cross checking.

Temperature Monitoring Application

Temperature data will be recorded 24/7 once the system is live, with no geographical limits. Access your temperature monitoring dashboard remotely and export the temperature logs without the need to be physically present!

Video

Watch our promotional video below!

Benefits

FAQ

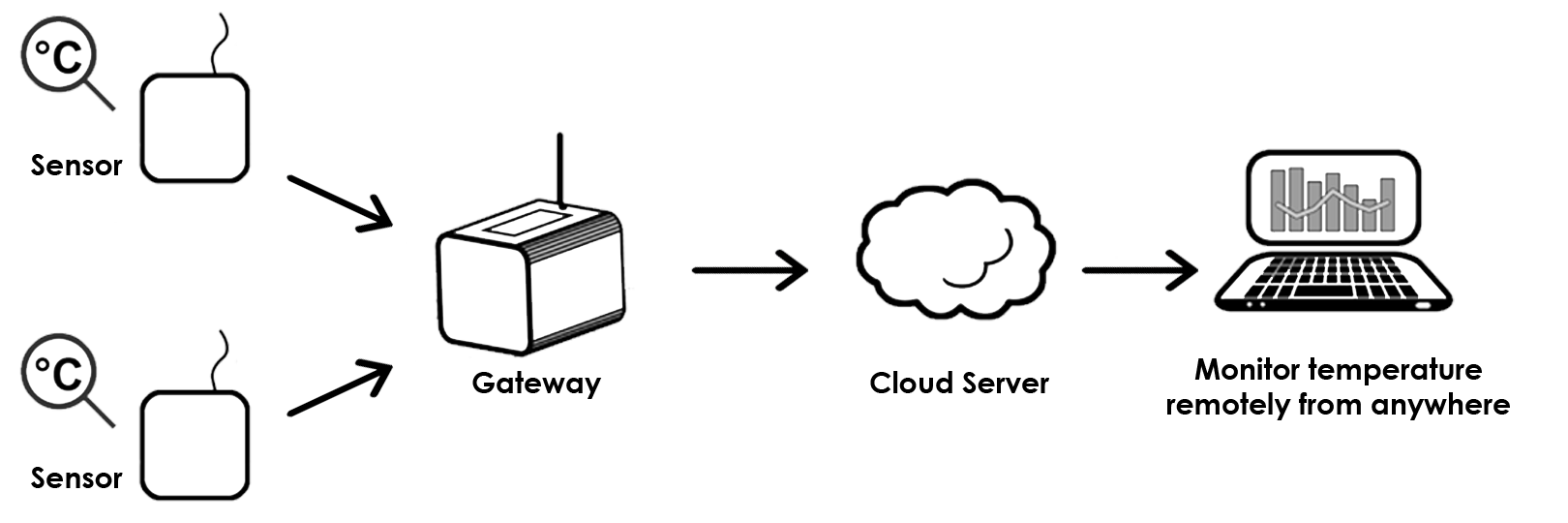

Temperature data have to be uploaded online to be accessed from anywhere.

And for us, our standard ThermoCare solution is hosted on cloud servers. The temperature data from the sensors are uploaded to the cloud servers via the gateways. The data are then processed into useful information which users can access from the dashboard application (from anywhere as long as there is internet coverage).

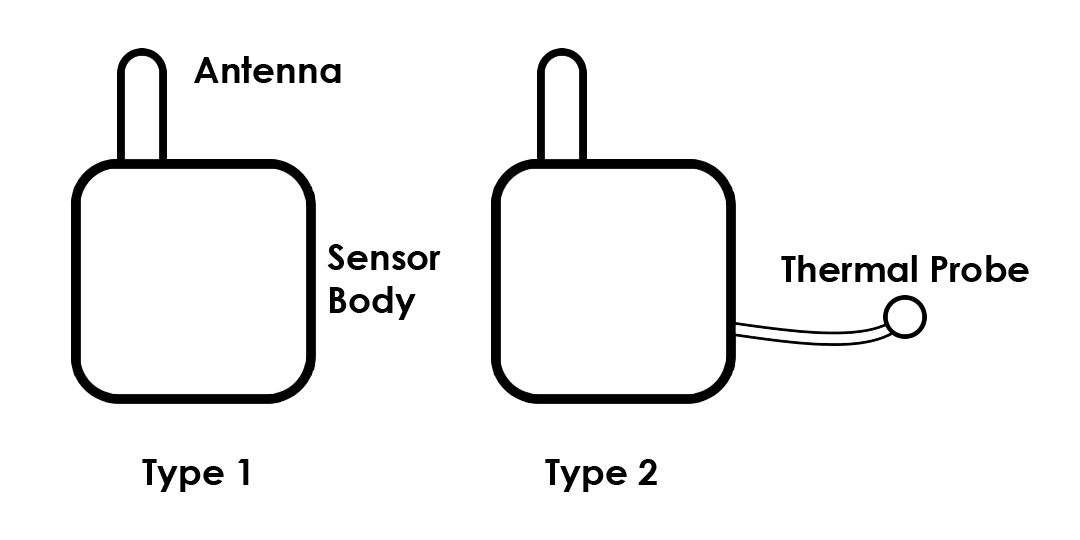

ThermoCare is utilizing 2 types of sensors:

Our sensors are battery powered and able to transmit the temperature data wirelessly to the gateways. The entire sensor unit contains components responsible for measuring the temperature, transmitting the temperature data to the backend and a battery slot.

The first type of sensor is designed to be placed into the measured environment as the sensor is housed within the body.

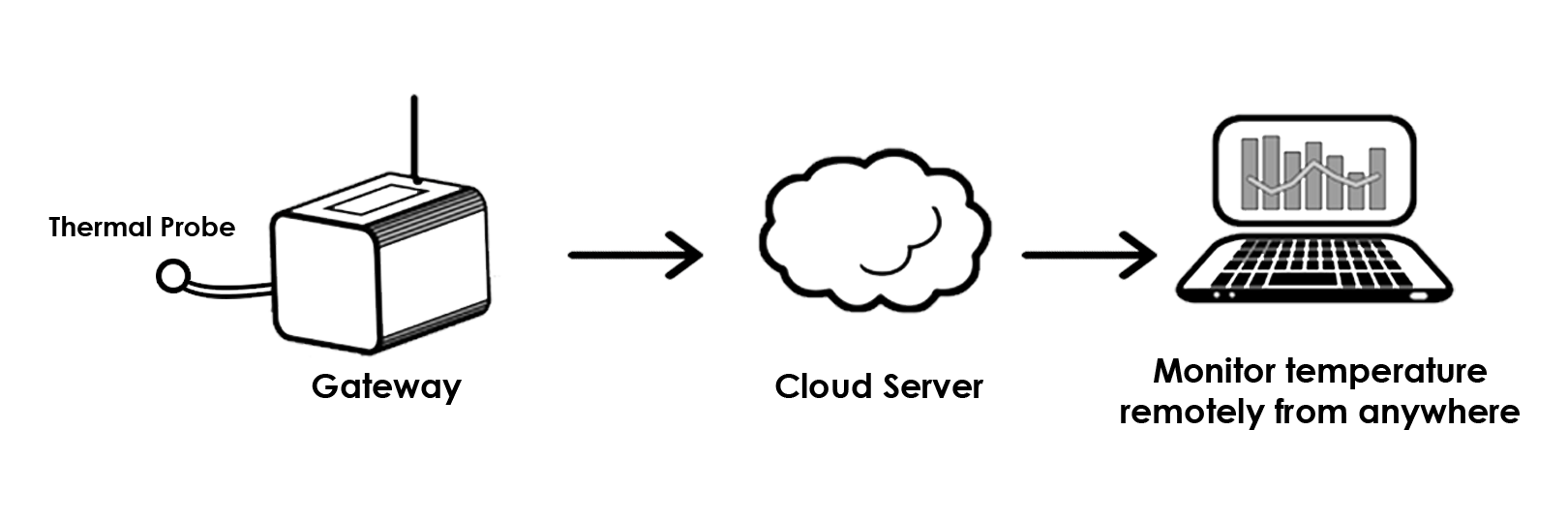

The second type of sensor is designed to be placed on the external surface of the freezer unit and we will run the thermal probe into the freezer unit .

For cold storage units that goes down to -20°C such as cold rooms, chest freezers, walk-in chiller, etc. We could simply place our sensors into the cold environment.

For cold storage units that goes below -30°C such as ultra-low temperature (ULT) freezers, cryogenic freezers, etc. We would have to place the sensors on the external surface of the units and run the thermal probe into the units through the access ports on the units.

As COVID-19 continues to evolve, so do we. New vaccines are released periodically to combat new strains of the virus and ThermoCare aims to contribute to the cause against COVID-19.

As such, we made certain to cater our temperature monitoring range for the various vaccines.

- Pfizer : 2 to 8°C (up to 31 days) -70°C (for long term storage)

- Moderna : 2 to 8°C (up to 30 days) -50 to -15°C (for long term storage)

- SinoVac : 2 to 8°C (for long term storage)

- Novavax : 2 to 8°C (for long term storage)

Our sensors and gateways utilizes wireless technology such as BLE and LoRaWAN to communicate and transmit the data from the sensors to the gateways wirelessly. Our IoT devices are tested to ensure the signals have good wall penetration and a good range to fulfill the market requirements.

And the gateway will upload the data onto the cloud servers via WiFi subsequently to provide seamless data communication and maintain the wireless data transaction.

No, our solution is able to work with devices from different vendor. Hence, our solution is in a sense – device agnostic.

Yes! We have sensors with external wired probe as well. These sensors are generally utilized for temperature range outside of -30°C to 70°C. As the CPU unit within the sensors are unable to withstand temperature outside the range of -30°C to 70°C, the external thermal probe is inserted into the freezing unit while the sensor remains outside. Installation of these sensors with external thermal probe takes more effort due to the wiring.

Hence, we only recommend sensors with external wired probes for temperature monitoring outside of the -30°C to 70°C.

A calibration certificate can only be issued by an accredited ISO calibration laboratory.

These laboratories have to meet stringent requirements to achieve the recognized ISO standards to perform calibration for sensor equipment.

The primary international standard that auditors will check for is ISO 17025 for calibration of your sensors.

Any other forms of calibration such as using a reference thermometer to calibrate the sensors, does not warrant a calibration certificate for your sensors.

Yes, but there will be additional charges for this requirement as our sensors have to be calibrated in an ISO accredited laboratory to receive the calibration certificate.

Related Resources

Click on the blog articles below to learn more!