Temperature Data Logger

Food Manufacturers | Seafood Suppliers | Distribution Centers | Pharmaceutical Warehouse

Reliable and rugged data loggers to record data. Easy to extract data for compliance to regulations. 24/7 monitoring with alerts to achieve peace of mind.

Let's Get In Touch!

You may view our products or contact us using the contact form below.

"*" indicates required fields

Temperature data logger is a device.

Temperature data logging is a function.

Intertnet-of-Things (IoT) Engineer

Data loggers for temperature and humidity

Common data logging applications

Compliance to regulations

Prevent loss of goods

Preventive maintenance

Automate processes

Temperature data logging in IoT

What is a temperature data logger?

A data logger is a device that records data over time. In a temperature monitoring system, the data logger would be recording the temperature reading. It can be either AC powered or battery powered.

The data are recorded with either an in-built sensor(s), external sensor(s), or wireless temperature nodes. The data can then be subsequently extracted from the data logger directly or uploaded to the internet if the data logger comes equipped with a network module for WiFi or ethernet functions.

Key features to look for in a temperature data logger

Not to be confused with the temperature reading range for the sensors, this is the temperature range wherein the data logger device is able to function in. Some data loggers are designed to be in harsh environment while others are designed to be located in a normal environment and communicate with the sensors in the harsh environment.

It is important to understand that no one can offer an unlimited storage for data. So it is important to know the max number of data points that a data logger can store, and get one that can meet your requirements.

E.g. there is a need to record the temperature hourly and generate a monthly report at the end of the month. So the math would be 24 (hours in a day) x 28 (days in a month) = 672. You would need to get a Data Logger that can minimally store 672 data points before resetting the data points for the next month.

In a cloud IoT temperature monitoring solution, the temperature data can be saved in the cloud servers as long as the data logger is connected to the internet.

Data logging function is only utilized when the temperature monitoring system goes offline due to reason such as power outage. During the down time, the data logging devices will start to record readings locally.

A risk assessment has to be done to establish an acceptable timeframe to resolve connectivity issues. User has to ensure that the data logger provides sufficient storage for data points within the time window where the data logger is disconnected from the internet.

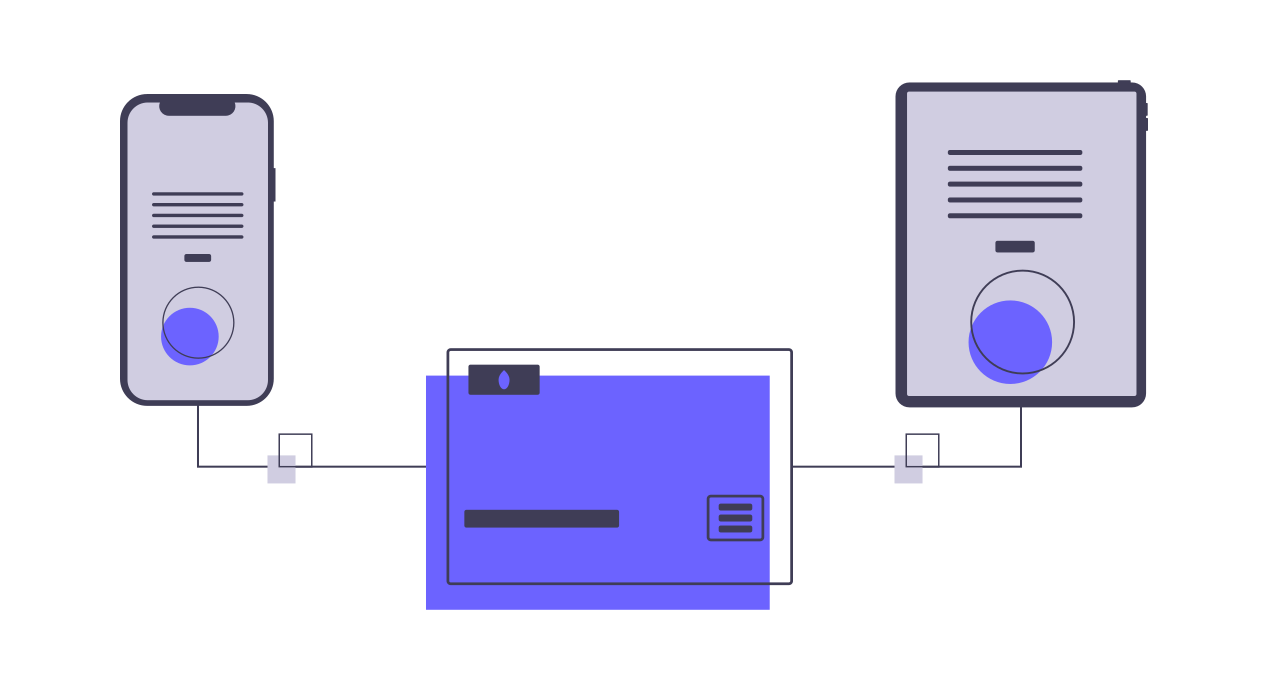

In some situation, it makes more financial sense to deploy wireless temperature sensor nodes across the facility than to install and run wires all over.

For this cases, a data logger that can wirelessly collect data from the temperature sensor nodes would be ideal.

Evaluate the application for your data logger, i.e. will the data logger be used for ambient monitoring? or used in closed equipment?

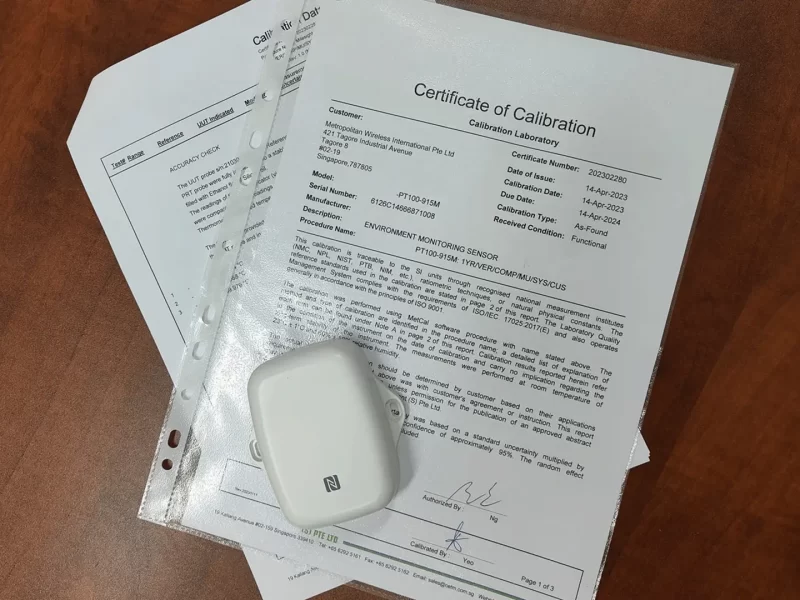

There should be a standard depending on the kind of use case for the data logger and you can determine the accuracy required of the data logger from there.

The aesthetics of the room is just as important as the security of the data logger.

Do a proper survey of your environment to understand the most suitable installation method for your environment to procure the right data logger as data loggers comes in different shapes and sizes with different installation options.

You can perform the site survey of your environment on your own or approach consultants like ourselves.

Frequently Asked Questions

A temperature data logger is a measurement instrument that is capable of autonomously recording temperature over a defined period of time.

It can be used to measure and record temperature in a variety of environments, such as industrial facilities, laboratories, and even homes.

A temperature data logger works by using a sensor to measure temperature. The sensor is typically a thermocouple, a thermistor, or a resistance temperature detector (RTD). The sensor converts the temperature into an electrical signal, which is then amplified and digitized by the data logger.

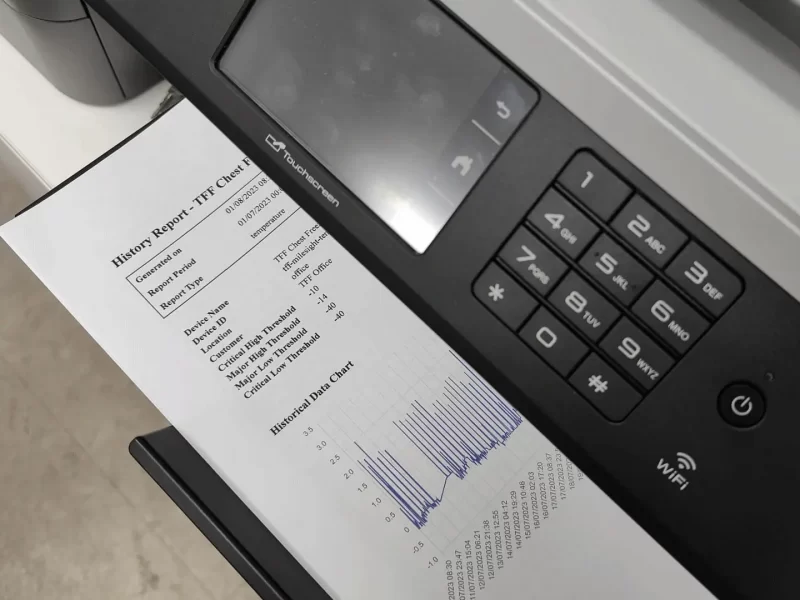

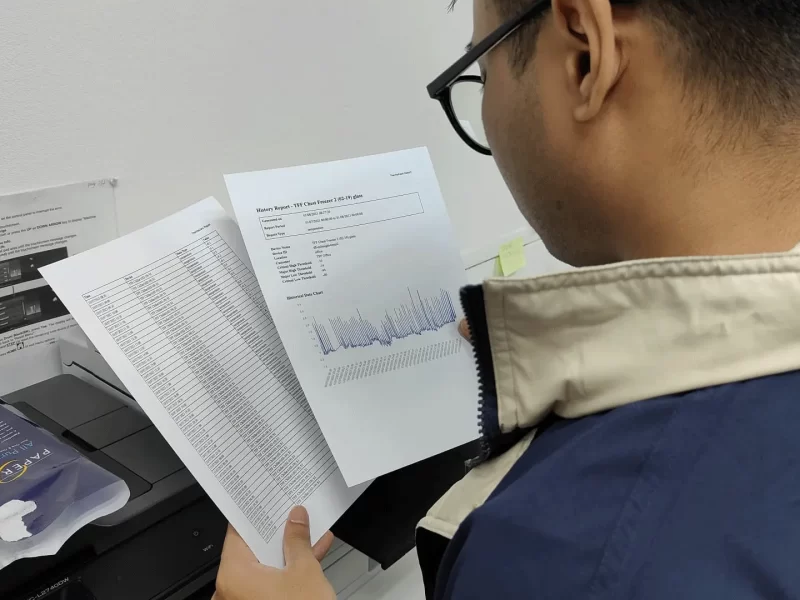

The data logger then stores the temperature readings in its memory. The data can be downloaded to a computer for analysis. Temperature data loggers can be used to track temperature trends, identify temperature spikes, and troubleshoot temperature-related problems.

With the introduction of IoT monitoring solutions, businesses are transiting to automation of their operations to improve efficiency and lower cost.

Traditionally, data has to be extracted manually from the data logger since they do not come with WiFi or Ethernet capability. Data loggers today are equipped with WiFi or Ethernet capability and can be programmed to upload the data stream to the internet and you can access the data remotely and monitor the temperature in real time.

A thermometer reads temperature but does not record the temperature.

A temperature data logger reads temperature and records the temperature.

Data Logging Comparison

| Temperature Data Logger | Temperature Data Logging in IoT Systems |

|---|---|

| A physical device that performs data logging | A function available in devices such as temperature sensors |

| Single point of failure | Redundant system |

| May have real-time data access | Will have real-time data access |

| Unable to schedule report | Able to schedule report |

| No alert notification | Smart alert notification via email or text |

| Good for non-critical operations that does not need real time remote monitoring | Good for business-critical operations that requires real time monitoring and alerts |