What Is The Temperature Required For Storing Ice Cream?

How Should Ice Cream Be Stored?

At Home:

- Airtight containers:

To prevent air from entering, tightly seal ice cream containers with a lid or plastic wrap. The original containers in which the ice cream was bought are one of the better options for storing it. - Avoid fluctuations in temperature:

Try to minimize temperature fluctuations in your freezer. Do this by avoiding opening the freezer door too frequently. Also, do not place the ice cream near the freezer’s door where the temperature may fluctuate more. - Separate from Odorous Foods:

Keep the ice cream in a different location than scented foods in the freezer as it will absorb odors of other items.

In a Store:

- Commercial Freezer:

Store ice cream in commercial freezers designed to preserve frozen foods.

- Rotation:

The ice creams have to be kept following the ‘First-In-First-Out’ method. This ensures that older ice cream is sold before newer batches. It helps ensure the freshest product for customers. - Hygiene:

Maintain high levels of hygiene and cleanliness in the freezer and surrounding areas. This is to prevent any contamination. Regularly clean the freezer, shelves, and any scooping equipment.

With these tips, it will ensure that the ice creams are well-kept and ready to eat.

FAQ

- Food Safety Compliance

- Production Efficiency

-

Product Distribution

It is important to store manufactured ice cream at controlled temperatures to maintain quality until it reaches consumers. Temperature monitoring is crucial during transportation to warehouses and retail outlets in designated trucks. Temperature sensors are placed inside these trucks to monitor temperatures. This ensures that they stay within optimal temperature range and prevent the ice cream from melting. Staff will also put the ice cream to designated sections of the truck to prevent exposure to temperature fluctuations when they open the door for unloading.

Conclusion

Temperature monitoring is an important aspect during the ice cream manufacturing process. So, the next time you enjoy your favourite ice cream, take a moment to appreciate the time and effort that goes behind-the-scenes to craft the ice cream you’re savoring to perfection.

If you are looking for a temperature monitoring system either for the ice cream manufacturing process or for the refrigerated trucks, MWI has the solution for you!

- Emergency Power Source

- Regular Maintenance

There should be regular maintenance of refrigeration equipment to identify and address issues before malfunctions occur. With regular maintenance, it will reduce the risk of equipment failures. The chances of losing assets is also lower.

- Invest in Temperature Monitoring System

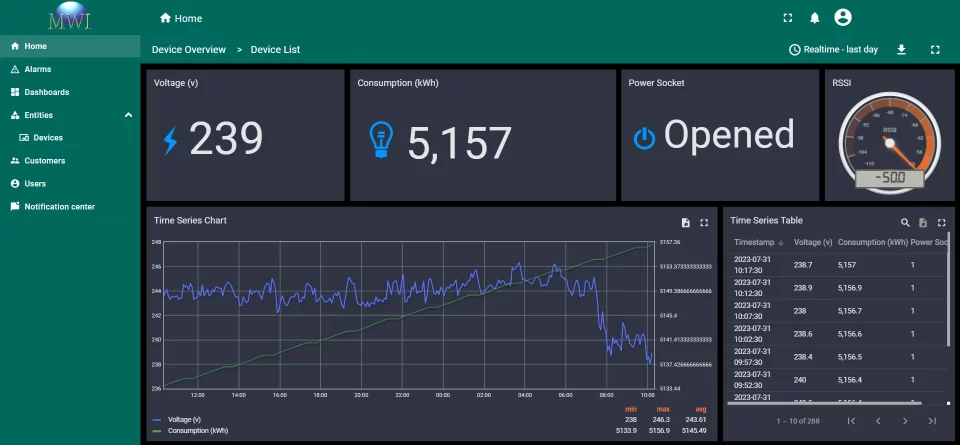

Investing in temperature monitoring system will also help the business in many aspects.

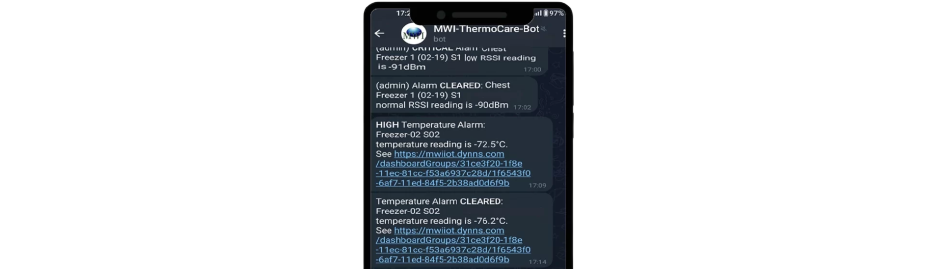

Firstly, the system sends out alert notifications to alert staff when the temperature goes above a set threshold. Staff can quickly address issues upon receiving alarms via Telegram or email on their mobile phones.

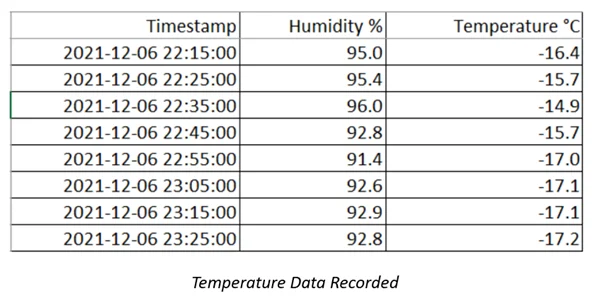

Secondly, the system captures and records temperature data in all the equipment. Temperature logs of these data can be exported when staff wants to track any fluctuations or anomalies of any of the equipment’s. This can be valuable for assessing the impact of an outage or malfunction.

Lastly, the system also has an option to do power monitoring. It monitors energy consumption of each equipment and allows staff to identify any irregularities/significant fluctuations in the equipment’s power consumption. Staff will also get alerts when there is a sudden increase or decrease in power consumption.