Temperature data logger and sensors are not apart from each other, but parts of the entire temperature monitoring solution.

ThermoCare Engineer

Types of Temperature Sensors

Identify the best sensor type for your use case

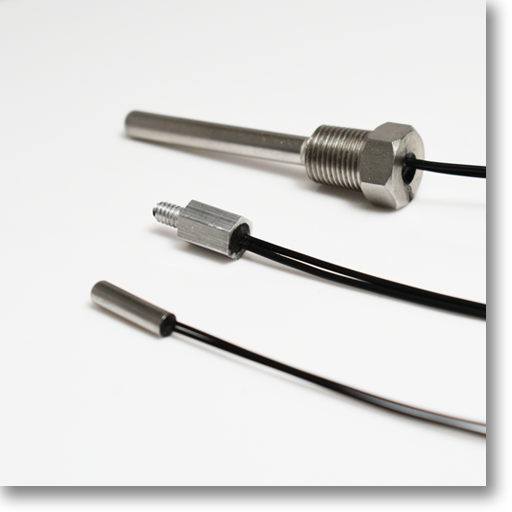

NTC Temperature Sensors

NTC Thermistors are non-linear resistors, which alter their resistance characteristics with temperature. The resistance of NTC will decrease as the temperature increases. This exhibit a negative temperature coefficient of resistance creating a non-linear relationship between resistance and temperature can be beneficial when accurate temperature measurement is needed within a relatively narrow range of temperatures, say within a window of 50°C. The nearly exponential change in resistance value for every degree centigrade in temperature change allows temperature to be measured with little error.

Benefits of NTC Temperature Sensor

Cost

Cost is one of the main driving forces behind the popularity of thermistors. They are capable of providing accurate and precise data for a small temperature range at minimal cost.

Size

Thermistors have a compact design and are fabricated in many forms, including beads, discs, and rods. Though they are available in small sizes, thermistors are exceptionally durable and long lasting.

Inrush

When a device is turned on, it is charged with an abnormally high amount of current, which is referred to as the inrush. Without protection, damage and harmful results may occur to the device. NTC thermistors are used as inrush current limiters (ICLs) to protect sensitive circuits. Inrush currents can damage capacitors, harm power switch contacts, and destroy rectifier diodes.

Protection from Overheating

The flow of current in an electrical circuit produces heat that is dissipated. The created heat increases the temperature of the resistor. With a thermistor, the definite amount of resistance is reached, and the heat is reduced.

Multi-purpose

Though thermistors are mainly known as components for measuring temperature, they have found use as a means of measuring pressure, liquid levels, and power. They are used as overload protectors and provide warnings of malfunctions.

Accuracy

Thermistors are installed at a measured distance from a circuit. This form of installation avoids errors in the readings due to resistance in the lead. Since thermistors operate over a small temperature range, their readings are more precise. They respond rapidly to small and minute temperature changes.

Response Time

Since thermistors can respond to slight incremental changes in temperature, they provide data instantly with little delay. This particular property is also due to the small range of temperatures they monitor.

Easily Customizable

There is an endless variety of thermistors that can be adapted, changed, and configured for any type of temperature application. Their multiple types and sizes allow them to be used in any operation, condition, or situation.

RTD Temperature Sensors

An RTD (Resistance Temperature Detector) is a sensor whose resistance changes as its temperature changes. The resistance increases as the temperature of the sensor increases. Thus, exhibit a positive temperature coefficient of resistance creating a nearly linear for a wide range of temperatures. This linear response can be beneficial when it comes to ease of converting a resistance reading into a temperature value. This characteristic also makes RTDs more suitable for use in applications where measurements are made over a wide range of operating temperatures.

Benefits of RTD Temperature Sensor

Durable

RTDs are far more stable and are capable of providing accurate and precise readings for a long time.

Stability

RTDs tend to provide stable output for longer periods of time and they always exhibit excellent linearity.

Accuracy

For industrial uses, RTDs are far more accurate and can produce readings with an accuracy of 0.1°C. A thermocouple's accuracy is far less at 1°C.

Adaptability

The majority of temperature readings are taken in inhospitable environments where there is corrosive, oxidizing, and reducing atmospheric conditions. In addition to the uncomfortable conditions, there are vibrations, noises, and electricity. RTDs are wire wound in protective casings and are rugged and immune to harsh and hazardous conditions. For added protection, RTDs can be coated with perfluoroalkovy (PFA) polytertrafluoroethlyene for use in plating baths and pressurized systems Therefore, they are considered ideal for temperature measurements in industrial environments.

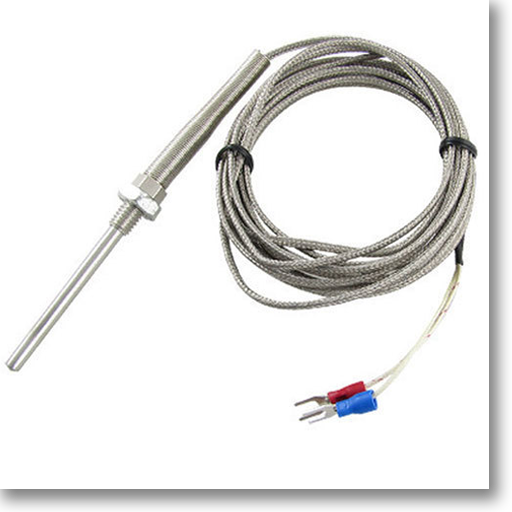

Thermocouple Sensors

A thermocouple is a transducer that converts thermal energy into electrical energy and is constructed by joining wires made from dissimilar metals to form a junction. Voltage is produced when the temperature at the junction changes. The concept of the thermocouple is based on the Seebeck Effect, which states that if dissimilar metals are joined at a point, they will generate a small measurable voltage when the temperature of the point of connection changes. The amount of voltage depends on the amount of temperature change and the characteristics of the metals. The structure of a thermocouple consists of two insulated wires connected to a measuring device. Thermocouples serve as a safety and monitoring gauge for various processes and equipment.

Benefits of Thermocouple Sensor

Self-powered

As the output emf increases according to temperature changes, there is no necessity for an external power source. Thus, thermocouples are self-sufficient in their operation.

Simple and Robust

In terms of design, these sensors are simple yet tough. They are constructed with different types of high strength metals, including aluminum, iron, copper, and platinum. This allows the sensors to be used in a variety of demanding industrial applications.

Affordable

Thermocouples are known to be inexpensive in terms of price. When compared with RTDs, they are found to be nearly three times less expensive than RTDs.

Wide Temperature Range

Thermocouples directly measure the temperature in an application. They have the capabilities to measure temperatures up to 2600°C.

| Category | Thermistor | RTD | Thermcouple |

|---|---|---|---|

| Material | Metal Oxides | Single Metal (Usually Platinum) | Two Dissimilar Metals |

| Temperature Range (Typical) | -100 to 325°C | -200 to 650°C | 200 to 1750°C |

| Accuracy (Typical) | ±0.05 to 1.5°C | ±0.1 to 1°C | ±0.5 to 5°C |

| Linearity | Exponential | Fairly linear | Non-linear |

| Response Time (Typical) | 0.05 to 2.5 seconds | 1 to 50 seconds | 0.1 to 10 seconds |

| Powered | Constant voltage or current | Constant voltage or current | Self-Powered |

| Susceptibility to electrical noise | Rarely susceptible High resistance only | Rarely susceptible | Susceptible / Cold junction compensation |

| Cost | Low to moderate | High | Low |

SUMMARY:

For most, the type of sensors are just good-to-know knowledge. You do not have to be well versed in the type of sensors if you are just looking to procure a temperature monitoring system, that is the job of the system providers. However, you can refer to the table above if you have to ascertain the details of your temperature monitoring.

Let's Get In Touch!

You may view our products or contact us using the contact form below.

"*" indicates required fields