The annual event that keeps the food businesses on their toes, the Food Safety Audit (Especially for Temperature Monitoring). Managers receive the notice, Employees scramble to prepare documents for the audit, the Food Safety Officers visit, and they either pass the assessment or fail the test with a list of follow up actions to perform.

Disclaimer; the following article is not an actual representation of the Food Safety Audit process by official bodies. This is a sharing of our experience from our own Food Safety Audit process that we went through.

While our emphasis is on Temperature Monitoring, let’s understand the whole process of an average Food Safety Audit and what to look out for.

Coldroom / Storage General Cleanliness

Food Product Labelling

Track & Trace Goods

Temperature Logs

Food Storage Cleanliness

The first and most obvious passing criteria is the cleanliness of the food storage area. There are no hard and fast rules to ascertain the cleanliness of a food storage area, as long as the area is free of dust, products are properly separated (raw from processed, etc.), products are on top of a pallet, the Food Safety Officers will consider the room clean for the most part.

Food Product Labelling

While the Food Safety Officers are in the food storage, they will scan through all the food products for an official and validated label. We will not go into the details for the label, but there should be basic information such as the product brand, barcode, and quantity on the label.

Inventory Management

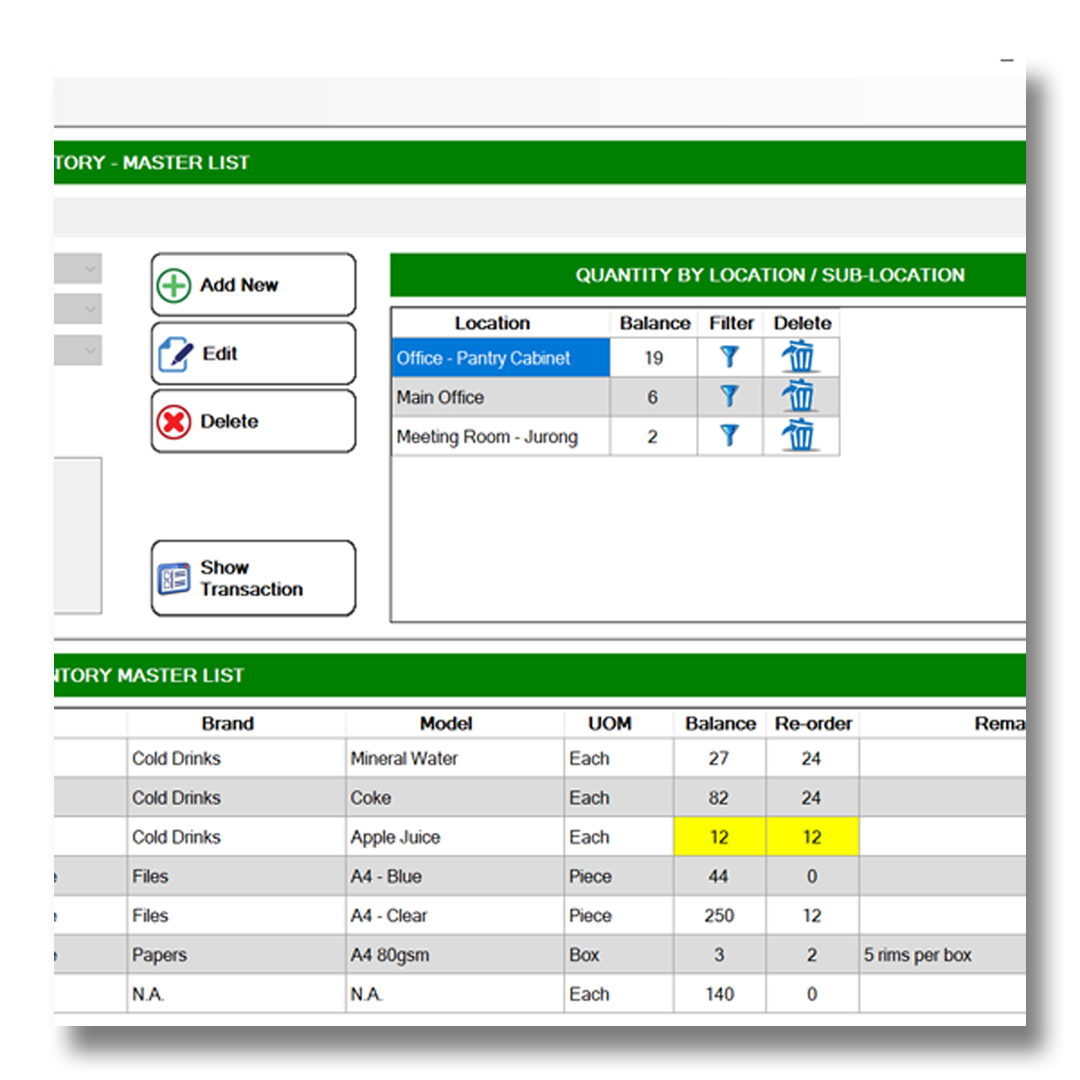

Accountability for your food products is something they may be looking out for as well. As such, an inventory management system (that your food business should likely have) would suffice. It is important for the system to show all incoming and outgoing product logs for the Food Safety Officers who may want to trace the food product back to the original source. One of our customers is currently using ALL ID Asia’s solution for this.

They are Singapore’s leading distributor for Barcode scanners, printers, and more. The PESONA Inventory Management System provides both the hardware and software required to manage your inventory at a competitive price point! The RFID technology is utilize for their solution.

Temperature Monitoring

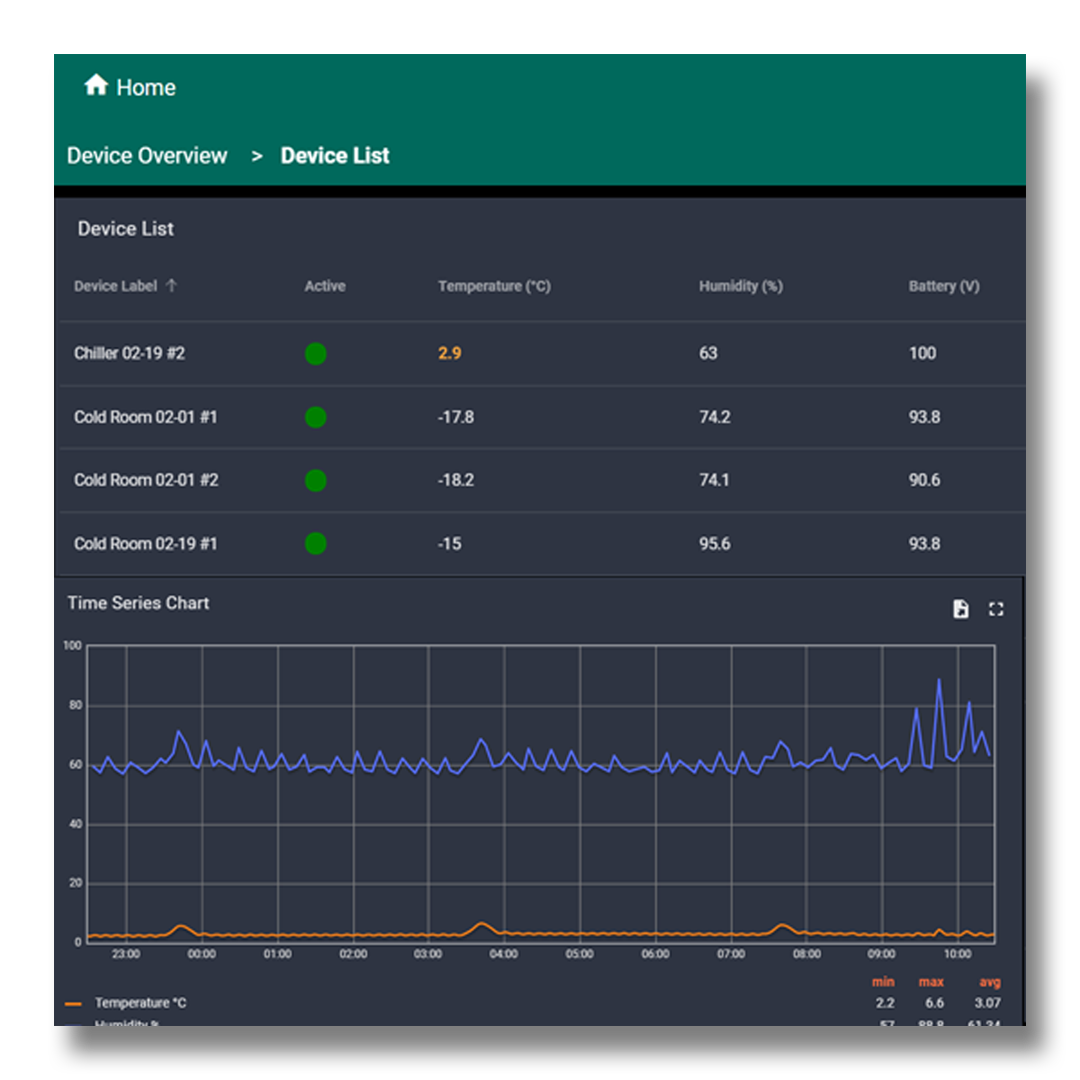

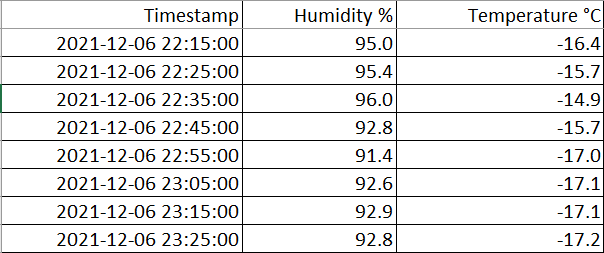

The most important thing that the Food Safety Officers want to inspect is the temperature logs of your food storage and the calibration of the sensors. Depending on the auditing body and where the food products are stored, they may check the temperature logs of either the cold room only or all of your cold storage including standing chillers and chest freezer.

The Food Safety Officers are not actually going to perform a calibration test on the temperature sensors during their visit, businesses are expected to produce a calibration certificate to prove the compliance of their temperature sensors. As such, businesses are to hire a third party to perform calibration tests on the temperature monitoring sensors. Upon passing the calibration test, businesses will be presented with the calibration reports and a certificate from the third party.

Present the temperature logs (6 – 12 months), calibration report, and certificate to the Food Safety Officers, and the business should pass the Food Safety Audit.

To summarize the process for the Food Safety Audit pertaining to the Temperature Logging aspect:

- Hire a third party temperature sensor calibration service provider to perform calibration tests

- Receive the calibration reports (including their thermometer details) and certificate

- Prepare 6 – 12 months of temperature logs of your cold storage

- Present the documents during the Food Safety Audit

A tip from our customer – segregate your food products into different storage for different companies that you will be supplying to. You will only need to prepare the documents specific to the food storage of where the requesting company’s food products are stored.

E.g. Company A has 3 cold rooms – Cold room 1, 2, and 3. Company A is supplying food products to their customer Company B, and the food products for Company B are only stored in Cold room 2.

Company B wants to perform a Food Safety Audit on Company A. So Company A only needs to prepare the documents for Cold room 2 and exclude Cold Room 1 and 3 for the Food Safety Audit.

Hope this article was able to provide some insight on the Food Safety Audit, and please do share your experience for a Food Safety Audit with us; whether it differs or is similar.