Introduction

Pressure monitoring system is needed in labs to ensure that the environment stays free of contamination. Companies should invest and be equipped with a lab or pressure monitoring system in place, to ensure that recorded data is available in order to abide with compliance and guarantee product safety and quality. Having a pressure monitoring system is crucial in reducing risks, that is why you should consider using our single point of control monitoring system. It can be accessed by the web application on any device (phone or laptop) at any time, providing you ease of access remotely.

1. Audit or Regulatory Compliance

HSA (Health Science Authority) has a strict audit system to ensure the safety of both employees and patients. Pharmaceutical labs have to adhere to stringent regulatory which monitors the safety, quality and efficacy of the product. This is important as pharmaceutical companies who do not abide by the audit requirements would be subjected to penalising such as recall of sales product or suspension. For this reason alone, data accuracy is crucial for audit. Without data accuracy, it would lead to operational inefficiency and loss of credibility for the brand. With our IoT lab monitoring system, rest assured that we are able to help you meet audit requirements. We provide both hardware and software as part of our solution so you will not need to look for different vendors for one solution.

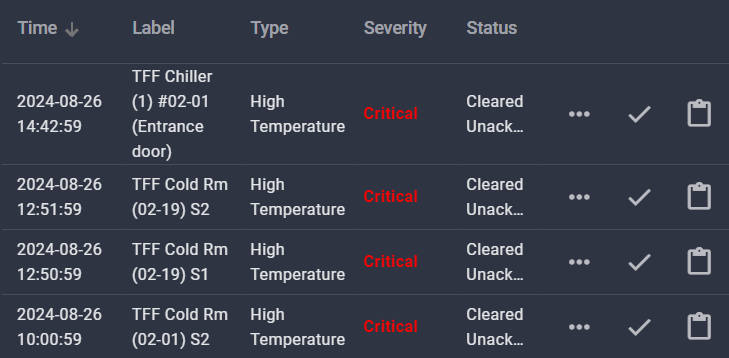

2. Alert Log To Analyse Triggers

Alert logs contains the most important information such as the time and location of sensor that went off. With alert log, users can analyse data to understand how the incident occurred and take steps to prevent future mishaps. This is also used for prevention of cross contamination which is essential in cleanroom as it can affect both staff and product quality. With pressure monitoring device, it helps with early detection of hazards as it can detect abnormal level of pressure, indicating that there might be a leak in pressurised equipment or more. When there is deviation from the pressure that was set, having a monitoring system will help to alert employees on the issue. To reduce risk of product quality being affected; the room pressure has to be set at a certain pressure throughout the whole process. With our solution, users will receive alerts via email, Telegram, or voice call and more, as soon as the pressure drops below the predetermined threshold. This enables staff to take immediate action, including contacting for maintenance assistance thus rectifying the issue faster.

Alarm Notification

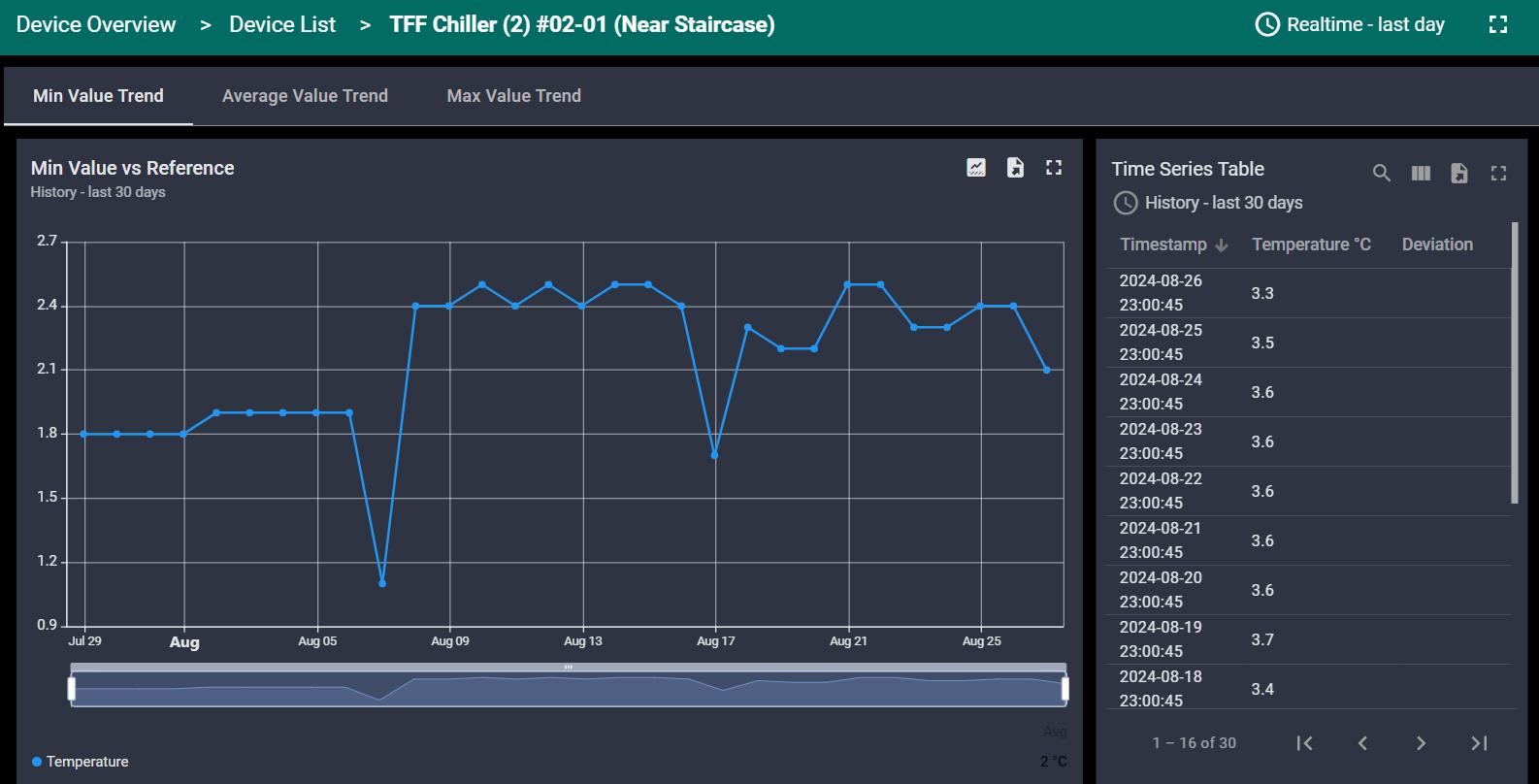

Temperature Trend

3. Process Control

Process and quality control goes hand in hand; having an effective process control such as standardised lab requirements, quality control would be easier to implement and fewer errors would be made. This also means that some process requires the pressure to be a certain reading in order for the reaction to proceed correctly. In chemical labs, pressure plays an important role as the rate of the process can be affected by the pressure of the surrounding environment. More importantly by monitoring and controlling the pressure, labs can be assured that their products which were made in batches, are produced in the same environment therefore consistent. This is important as HSA (Health Science Authority) has guidelines ensuring that products made are of the highest quality. With our pressure monitoring system, this reading can be accessed and downloaded at any time, remotely.

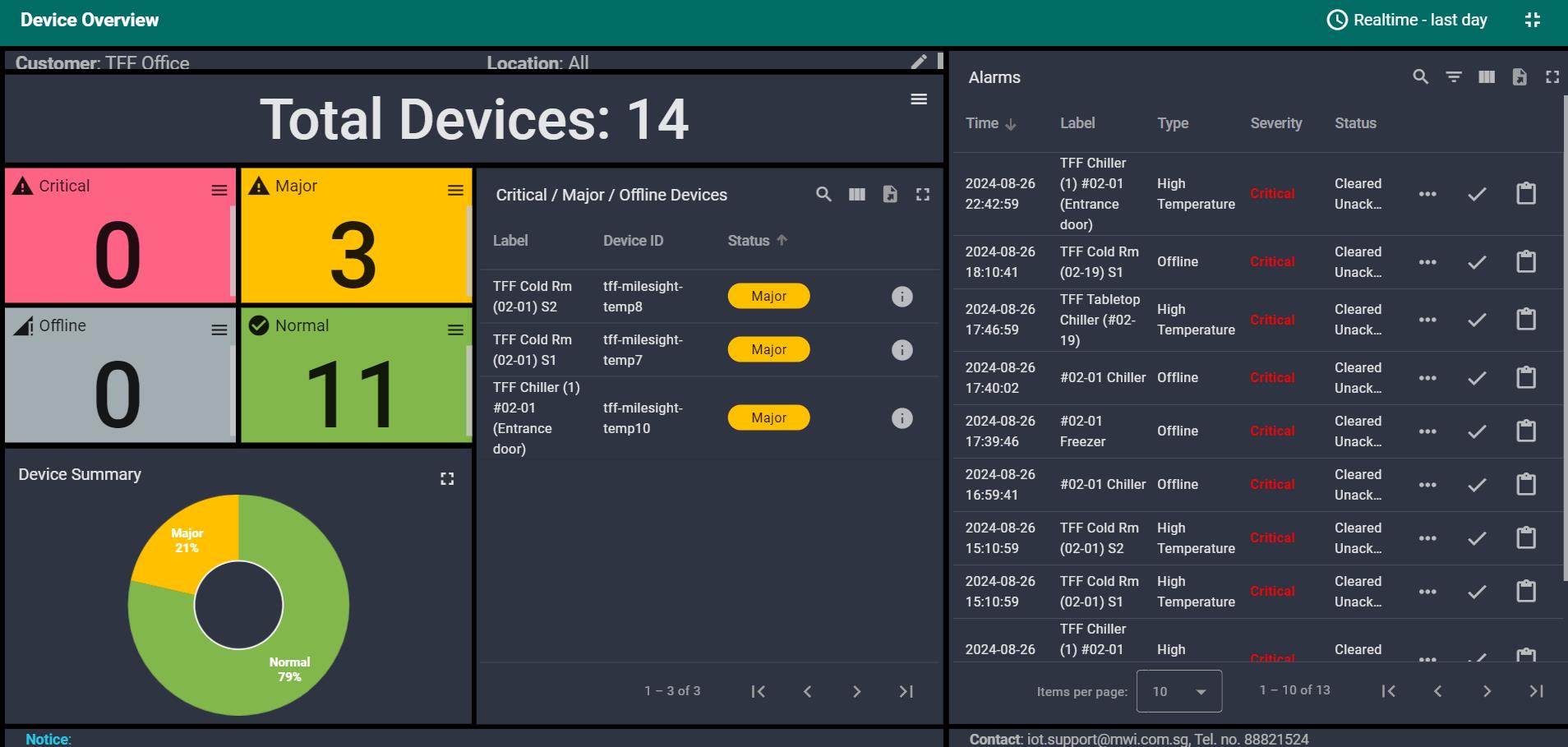

4. Data for Process Improvement

With continuous pressure monitoring, this data can be used during audit checks, where the data on environmental conditions is readily available. When using this data to identify trends and patterns, it is essential to recognize potential issues before they escalate into significant problems. With our software, users can view this data at any time through the web application and make the necessary changes to ensure that the pressure is within the threshold. When using our monitoring system and software, users can look at the alarm notification history to see the dates when the alarm was triggered and they can acknowledge the alarm notification. They can also look at the data for the pressure, which can be interpreted in graph, excel sheet and more, to better suit the needs of the customer. Ultimately, this data can also be used during audit screening.

Dashboard Overview

Conclusion

Pressure monitoring system is needed in every molecular labs to ensure that the environment stays free of contamination. Companies should consider pressure monitoring system, to ensure that records of the pressure room or cleanrooms abide with compliance from government bodies, ensure product safety and quality. Implementing pressure monitoring system is crucial in reducing risks that is why you should consider using our single point of control monitoring system. It can be accessed by the web application on any device (phone or laptop) at any time. With the pressure monitoring system, tracking environment stability within the lab is not an issue as the environment monitored and alert notifications will be in real time.